| Product Type: | ND |

|---|---|

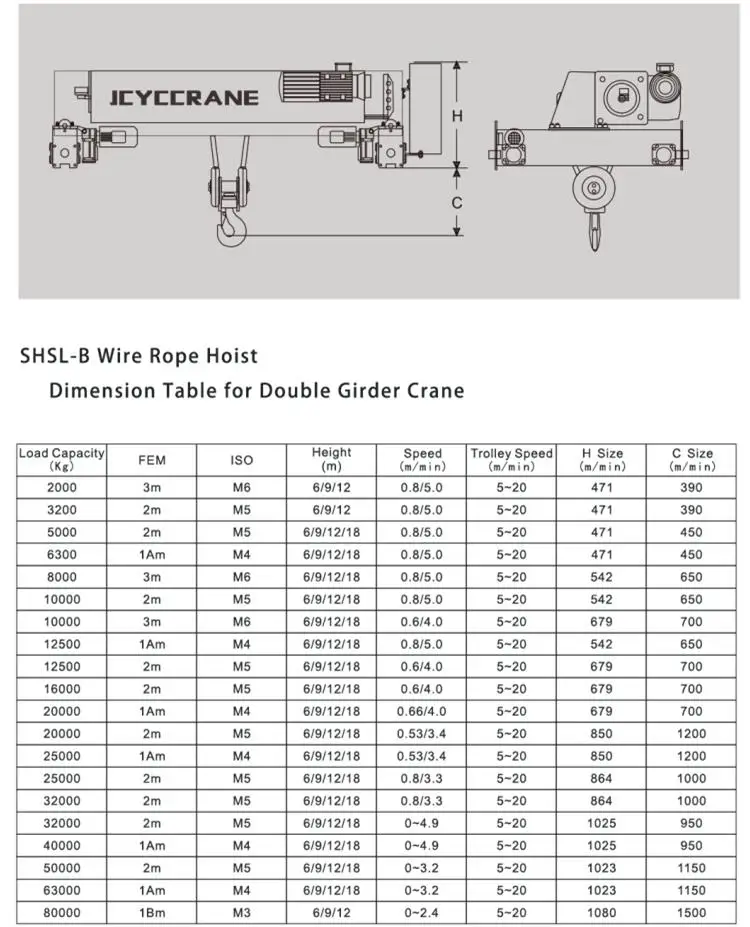

| Lifting Capacity: | 1~80t |

| Span: | 6~50m |

| Lifting Height: | According your demands |

| Working Class: | M5,M6 |

| Ambient Temperature: | -20~40℃ |

European wire rope electric hoists is a kind of new products developed with advanced design technology according to the latest national standard GB/T3811 "Design specifications for cranes", and refers to European FEM standard. The whole set of electric hoist is a new energy-saving and environment--friendly product whose technology is internationally advanced and cost performance is in the top among the same products.

General layout is in parallel ( C structure), in other words, rope drum parallels motor through the reducer.

There are below features: small limiting dimension, compact structure and high space utilization.

Products adopts modular design whose stress structure is reasonable and grouping property is good.

The lifting and braking is stable. Parameters are properly designed to make maintenance simple and convenient.

Lifting motor adopts original packaging imported from Germany 2/12 class motor.

European optimizing design makes lifting motor small dead weight and wheel pressure.

Lifting speed is double speed or frequency conversion.

Positioning is precise, and cover adopts aluminous to lower dead weight at maximum.

Interior gears of motor are made through grinding processing whose hardness reaches over 60HRC and accuracy is 7 class.

The whole set has more stable property, higher efficiency and longer service life.

Helical gear; hard-tooth surface

Small dead weight; good sealing

Strong stability; a long service life

Automatic abrasion compensation electromagnetic chuck brake

Integrated design of normally closed brake and motor, good synchronism

Good sealing; dust-proof; heavy working class

A large are of friction connect; adjustable braking torque

Rope drum consists of sleeve, right and left end cap.

When assembling, rope drum next to motor through spline housing is connected with spline shaft of motor, and transfers torque through spline mesh. 1mm interval is left between spline housing of drum and spline shaft end of motor to prevent bearing stress of motor output shaft.

When the hook is to the lowest, at leat two coil wire rope are around the drum.

Free-maintenance and soft rope guide is adopted to avoid wire rope out of the tank.

Four-class adjustable rotary rising limiting is fixed on the flange through steel plate -bent support base.

Rising limiting output shaft is non-standard customized waist shaped shaft. Certain depth of waist shaped groove is milled on the drum supporting axle, and the rotary number of rope drum delivers to rising limiter through cooperation to play the role of controlling electric hoists rising limiting.

High-strength wire rope; 2160 N/mm2 breaking force;

Galvanized , free--maintenance

1/4 rope--output high-strength hook according to Germany DIN standard;

Compact structure; high safety class;

Small swing of lifted weights;

Safe lock; mousing hook.

Reaction wheel device consists of reaction wheel, supporting frame, and spring. Adjusting decrement of spring makes electric hoist travel. There is always a force of reaction wheel impacting on the cover plate under the main girder so as to get active wheel enough wheel pressure avoiding slipping. Unique-design reaction wheel device replaces weight box of traditional low head hoists.It has efficiently low dead weight and at the same time ensure the whole set to travel stably.

Controlling electric parts adopts Germany Schneider original packaging; Reliable property, high flexibility, a long service life; Optionally, equipped with overload limiter recording crane working records and automatic monitoring recorder long keeping record data; Called as “black box” of cranes.